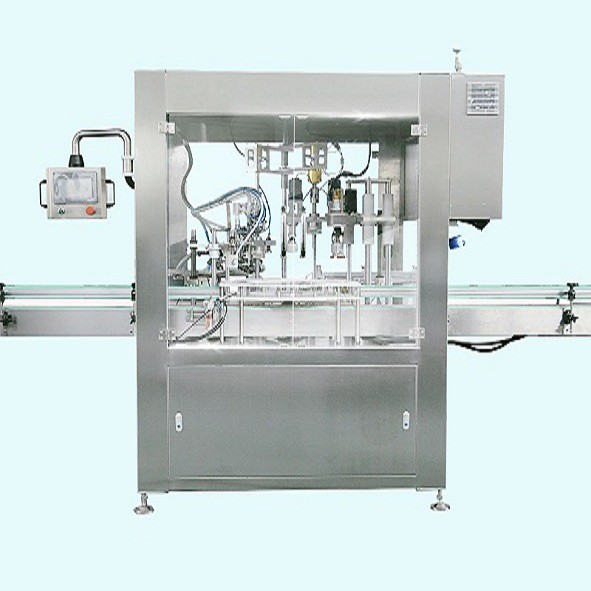

Monoblock Filling Machine: Revolutionizing the Packaging Industry

Introduction:

In recent years, the packaging industry has witnessed significant advancements in technology, leading to inc Monoblock Filling Machine Supplier reased efficiency and productivity. One such innovation is the Monoblock filling machine, which has revolutionized the manufacturing process of filling various products. This article delves into the manufacturing process, features, advantages, usage Monoblock Filling Machine Manufacturer methods, tips for selecting this product, and concludes with a comprehensive analysis of this groundbreaking invention.

Manufacturing Process:

The Monoblock filling machine is manufactured using advanced techniques that combine precision engineering with cutting-edge automation. The production process involves meticulous attention to detail to ensure optimal performance and superior quality standards. Established Monoblock Filling Machine Manufacturers employ state-of-the-art facilities to deliver high-quality machines tailored specifically for different industries.

Featu Compact filling machine res:

1. Single-piece filling machine: The Monoblock filling machine boasts a single-piece design that eliminate

s complex assembly processes typical of traditional machines.

2. Compact size: This innovative equipment occupies minimal floor space while maintaining its functionality and capacity.

3. Consolidated system: By integrating multiple functions into one device (such as rinsing bottles before filing), it increases overall operational efficiency.

4. High-speed operation: With advanced mechanisms in place, these machines off Single-piece filling machine er rapid processing capabilities without compromising accuracy or product integrity.

Advantages:

1. Increased productivity: The utilization of automated systems reduces manual labor requirements significantly while increasing output capacities due to faster cycle times.

2. Enhanced product quality: Through precise control ov Monoblock filling machine er filling volumes and reduced exposure to external contaminants during packaging operations guarantees consistent quality across each unit produced by using monolock filing machines,

3. Cost-effective solutions: Streamlined workflows minimize downtime between production runs resulting in cost savings by maximizing output potential Moreover offering flexible configurations suit

Usage Meth

ods:

Using a Monoblock filling machine largely depends on specific application requirements; however few common steps need abstraction i.e.: Connect input supply sources (power, air), Set up and configure the system based on product specifications (filling volumes, bottle types), Load empty containers into the machine’s feed mechanism, Select desired filli Consolidated filling machine ng parameters, Initiate the automated operation, Monitor process for any irregularities or malfunctions.

Selecting a Monoblock Filling Machine:

When choosing a Monoblock filling machine supplier or manufacturer to meet your production needs,it is essential to consider several factors such as reliability,reputation,custo Monoblock filling machine mer support services.Evaluating product certifications,warranty policies,and available customization options can further help you make an informed decision. Additionally,you should assess compatibility with existing production lines and potential future expansions.

Conclusion:

With its unique features and advantages,the Monoblock filling machine has undeniably transformed the packaging industry.While its single-piece design simplifies assembly processes,the compact size ensures efficient space utilization.More Established Monoblock Filling Machine Manufacturer over,the consolidated system,s high-speed operation,and unquestionable quality result in increased productivity.However ,it is important to conduct thorough research when selecting a reliable supplier or manufacturer for your specific re Monoblock filling machine quirements.Choosing this cutting-edge technology will undoubtedly propel businesses forward by enhancing efficiency and streamlining operations.