Double Sided PCB: Manufacturing, Features, and Selection

Introduction:

In today’s technological era, the demand for Double Sided Printed Circuit Boards (PCBs) has significantly increased. This article provides an in-depth understanding of the manufacturing process, features, advant Double-sided PCB manufacturer ages, usage methods, and how to choose the right Double Sided PCB for your needs.

Manufacturing Process:

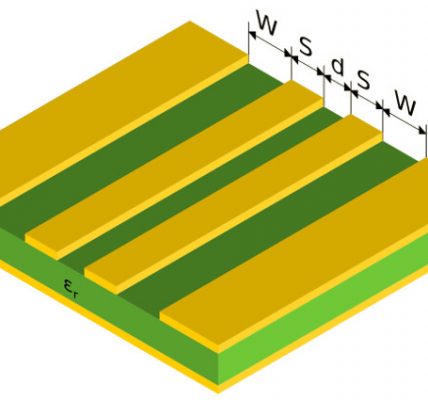

Double Sided PCBs are also known as Two-layer printed circuit boards or Sandwich circuit board structures. The manufacturing process involves starting with a base material called Two-sided copper clad laminate (CCL). A thin layer of copper is applied to both sides of this substrate using specialized machinery. Next, a photoresist film is a Two-sided copper clad laminate (CCL) dded on top of each copper layer. Through a photolithography process followed by etching techniques, circuits are formed on both layers simultaneously. Finally, vias are drilled through the board to connect different layers together.

Features and Advantages:

The Double Sided PCB offers several remarkable features along with numerous advantages over other types of circu Double-sided PCB manufacturer it boards:

1. Versatility: It allows electrical connections on both sides due to the presence of conductive traces.

2. In Two-layer printed circuit board creased Design Flexibility: With two layers available for routing tracks and components placement, designers have more space for complexity.

3. Enhanced Reliability: By distributing components evenly across both sides eliminates potential overheating issues.

4. Compact Size: Compared to single sided PCBs or wire-wrapped designs; double sided boards reduce ov Double Sided PCB erall size without compromising functionality.

5. Improved Signal Performance: Proper ground plane placement reduces signal interference and noise susceptibility.

Usage Method:

Using a Double Sided PCB requires careful considerations during assembly and soldering processes:

1. Component Placement: While placing components on either side ensure proper clearance between them while adhering to manufacturer guidelines.

2.Soldering Techniques – Dual Layer PCBS often require reflow soldering techniques.are highly recomme Aluminum PCB manufacturer nded since hand-soldering can be tricky due to increased complexity.

3.Testing and Debugging – Special attention must be given during testing and debugging phases as access to components on both sides may require extra effort.

How to Select the Right Double Sided PCB:

Selecting the appropriate Double Sided PCB can greatly impact project outcomes. Consider the following factors before making a choice:

1. Appl Sandwich circuit board structure ication: Determine if your project requires high-density circuitry, reduced size, or improved signal performance.

2. Quality Standards: Ensure that the manufacturer complies with industry standards such as ISO 9001, UL certification, and IPC-A-600G Class II for reliability.

3. Material Selection: Evaluate different options like FR4 (fiberglass reinforced epoxy), High-Tg (high glass transit Double Sided PCB ion temperature), or Aluminum-based boards based on your project requirements.

4. Manufacturer Reputation: Research about manufacturers that provide excellent customer support, prompt delivery timeframe Double Sided PCB s, and reliable after-sales services.

Conclusion:

Double Sided PCBs have revolutionized electronic systems due to their versatility in accommodating complex designs while providing enhanced functionality in a compact layout. Understanding its manufacturing process empowers engineers to make informed decisions regarding material selection and assembly techniques for optimum results. By considering crucial factors when choosing a Double-Sided

PCB supplier ensures reliability while meeting specific application needs.

Remember – whether you are seeking a reputable Double-sided PCB manufacturer or looking for various board types such as Aluminum PCBs; thorough research will ensure you get accurate products fitting your demands perfectly!