Double Sided PCB: Manufacturing, Features, Advantages, and Selection Guide

Introduction

In the world of electronic circuit bo Double Sided PCB ards, one type that stands out is the Double Sided PCB. This article will explore the manufacturing process, features, advantages, usage methods, and how to select this product.

Manufacturing Process

The production of Double Sided PCB involves sandwiching two layers of copper conductive materi

al on either side of a non-conductive substrate. The layers are connected through vias or plated holes which allow electrical signals to pass between them. Advanced techniques like vapor deposition are used for creating multiple thin conducting layers on both sides.

Features

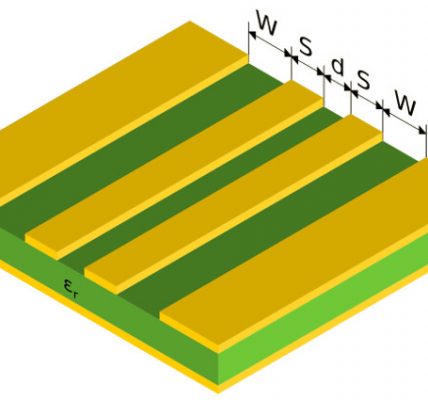

1. Dual layer PCB – As the name suggests, Double Sided PCB has conductive layers on both sides.

2. Twin-panel circuit board – The dual-sided arrangement offers a larger area for components placement.

3. Sandwich circui Double Sided PCB t board structure – With insulating materials in between conductor planes.

4. Top and bottom conductor PCB design allows better routing options and minimizes interference issues.

5. Bilevel PCB design provides more flexibility while designing complex circuits.

Advantages

1.Amplified D Double-sided PCB manufacturer esign Potential: The extra real estate offered by double-sided boards opens up possibilities for intricate designs with reduced component density constraints.

2.Space Efficiency: By utilizing both sides of the board effectively, these types of PCBs save space compared to single sided ones thus enabl

ing smaller electronics devices.

3.No limitations with Routing: The presence of conductive traces on both surfaces enables optimized routing without concerns about overcrowding tracks or excessive signal overlaps.

Usage Methods

Small-to-medium complexity applications find Double Sided PCBs suitable when there is a need to connect n Double-sided PCB manufacturer umerous components ensuring proper signal flow across various sections within an electronic device/appliance/system.These flexible solutions cater well in areas such as consumer electronics,laboratory,military systems,equipment control units,and many others where reliability,cost,balance have similar Aluminum PCB manufacturer importance during design considerations.

How to Select the Right Double Sided PCB

1. Consider Application: Understand the nature and complexity of the application where you plan to use Double-S Dual layer PCB ided PCBs.

2. Material Quality: Ensure that high-quality materials are used during manufacturing, facilitating a reliable and long-lasting product.

3. Manufacturing Expertise: Choose a reputable double-sided PCB manufacturer with experience in producing high-quality boards meeting specific requirements.

4. Technological Capabilities: Check if the manufacturer employs advanced techniques like laser drilling, controlled impedance, and surface finishing suitable f Sandwich circuit board structure or your project needs.

Conclusion

Double Sided PCBs offer enhanced design potential, space efficiency, and flexibility in routing for various applications. With their sandwich structure and top/bottom conductor design, they are widely utilized in consumer electronics, laboratory equipment control units,and military systems among others. When selecting these boards, meticulous consideration should be given to appli Double Sided PCB cational aspects,material quality,and technolog Twin-panel circuit board ical capabilities offered by manufacturers ensuring optimal performance through longevity.End-users can benefit from collaboration with experienced suppliers possessing expertise necessary to deliver highly reliable solutions adaptable uniformly across diverse electronic projects